6 7 T C P L a s e r M e s s e i n h e i t A n w e n d u n g OGLW2

Werbung

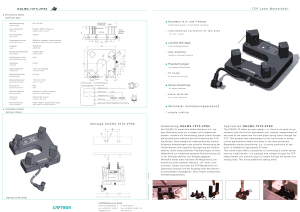

TCP Laser Messeinheit O G LW 2 - 7 0 T 4 - 2 P S 6 ■ Te chnische Daten technical data supply voltage <50m A load current output current max. 200mA per output, short-circuit protection Ausgang 2xPNP-NO output 2xPNP-NO S c h a l t z ustandsanzeige 2 gelbe LEDs statusdisplay 2 yellow LEDs S c h a l t f r equ e n z max. 1kHz 20 ■ Leichte Montage 90 durch einteiligen Aufbau 7 4H 90 switching frequency max. 5 30 3 4, 70 0,2mm ■ easy assembly 8 R15 200m A je Ausgang, kur zschlussfest Auflösung 5 20 Au sg a n gsstrom max. ( X - a n d Y- a x e s ) thanks to a one-part structure 39 S t r o m a ufnahme ■ simultaneous correction of two axes 7 redlight, 650nm, class 2 ■ Passbohrungen 35 50 16 laser light Stecker connector M8-5pol. M4 (4x) 42 Rotlicht, 650nm, Klasse 2 17 L a s e r - S endelicht b e i d e A c h s e n w e rd e n i n e i n e m S c h ri t t v e rme s s e n 7 DC 12V- 30V Laser 7,5 B e t r i e b s spannung ■ Korrektur in X- und Y-Achse 5 Nadelabstreifer needlescraper z u r e x a k t e n P o s i t i o n i e ru n g 5 ■ fit holes 7,5 5 20 0,01mm reproducibitlity 6 R e p r o d uzierbarkeit 6 <2,5V per output 15 <2,5V pr o Ausgang voltage drop for exact positioning 15 S p a n n u ngsabfall 45 resolution M4 (2x) 5 B e t r i e b s temperatur +10°C bis +50°C Ans c hl us s pl an - Stec k er bel egung operating temperatur +50°F to +122°F terminal diagramm - plug grouping S c h u t z a r t IP IP65 degree of protection IP65 G e h ä u s e-Material Aluminium, schwarz eloxiert housing material aluminium, black anodized 4 s c hw ar z - black Y- LS Anschluss Stecker M 8, 5- polig 3 bl au- blue connection connector M8, 5-pin 5 gr au- grey 1 br aun- brown 2 w ei ß - white ■ M i n i m a l e r Ve r k a b e l u n g s a u f w a n d + ■ simple cabling X- LS Last load 2 4 Last load 1 n.c . 3 5 ■ A uslief erzustan d delivery status M o n t a g e O G LW 2 - 7 0 T 4 - 2 P S 6 A n w e n d u n g O G LW 2 - 7 0 T 4 - 2 P S 6 D i e OGLW2 - 7 0 b i e te t e i n e o ffe n e Ba u fo r m , d .h . m i t d e m Werkzeug muss zur Justage nicht eingetaucht werden, so n d e r n d i e Ve r m e ssu n g g l e i ch zw e i e r Ach se n g l e i ch ze i ti g ka n n w ä h r e n d d e s D u r ch fa h r e n s d e r TC P sta tt fi n d e n . D i e s e r m ö g l i ch t i n sb e so n d e r e b e i ze i tl i ch b r i sa n te n An w e n d u n g e n e i n e sch n e l l e Ve r m e ssu n g d e r Ve r fahrachsen ohne jegliche Verzögerung der Arbeitsabläufe. Dank entsprechender Passbohrungen ist eine Möglichkeit zu r w i e d e r h o l t g e n a u e n Po si ti o n i e r u n g z.B. i n d e r Se r i e n p r o d u kti o n vo n An l a g e n g e g e b e n . A p p l i c a t i o n O G LW 2 - 7 0 T 4 - 2 P S 6 The OGLW2-70 offers an open design, i.e. there is no need for penetration with the tool for adjustment and, instead, measurement of two axes at the same time can take place during travel through the TCP. This enables fast measurement of the travel axes in timing-critical applications without any delay in the work processes.Repeatedly precise positioning, e.g. in series production of systems, is enabled by appropriate fit holes. Dat ei: O S-O GLW 2- 70T 4-PS6 St and:0609 10 4 4,3 50 35 O GLW2-70T4-2PS6 C A PT R ON Elect r o n ic Gm b H 6 J o h a n n - G . - G u t e n b e r g - S t r. 7 D - 8 2 1 4 0 O l ch i n g F o n : +4 9 ( 0 ) 8 1 4 2 - 4 4 8 8 - 0 F a x : +4 9 ( 0 ) 8 1 4 2 - 4 4 8 8 - 1 0 0 i n f o @c a p t r o n . d e www. c a p t r o n.d e 7