SENTRON communication manual

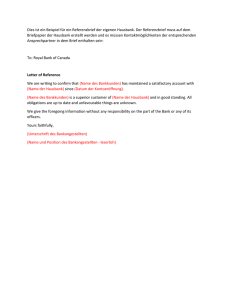

Werbung